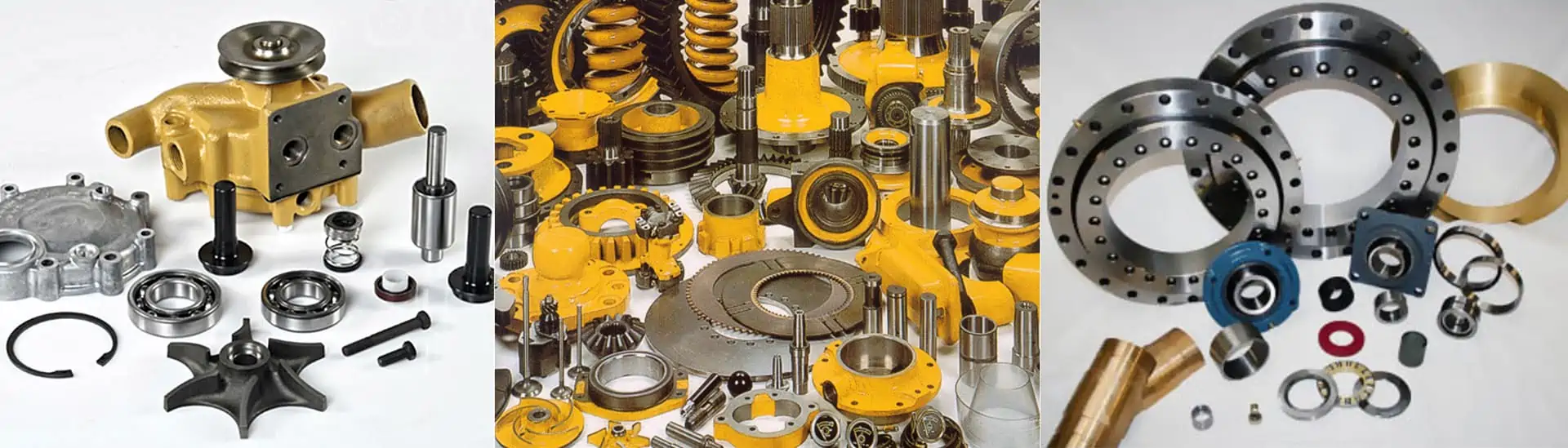

Leading 10 Aftermarket Construction Parts for Improved Performance

Enhance Your Hefty Machinery With Top Quality Aftermarket Construction Components

Enhancing heavy machinery with quality aftermarket building components can dramatically influence the efficiency and longevity of your equipment. From enhanced performance to economical options, aftermarket building and construction components offer a range of advantages that provide to the varied demands of hefty equipment drivers.

Advantages of Aftermarket Building Components

Enhancing hefty machinery with aftermarket building and construction parts can significantly boost efficiency and durability. Aftermarket components are commonly developed with upgraded products and technologies, which can result in equipment that can withstand much more extensive operating conditions.

In addition, aftermarket building and construction parts can use price financial savings compared to purchasing initial devices supplier (OEM) parts. While OEM components are normally much more pricey due to brand name acknowledgment and exclusivity, aftermarket choices provide an even more economical option without endangering on quality. This cost-effectiveness can be especially advantageous for business aiming to optimize their functional expenditures without sacrificing the efficiency of their hefty machinery.

Factors to Take Into Consideration When Selecting Components

When picking building components for heavy equipment, it is important to meticulously think about numerous elements to make sure optimal performance and compatibility. One critical element to take into consideration is the quality of the components. Deciding for top quality aftermarket building and construction parts can substantially influence the overall performance and durability of the equipment. It is essential to choose parts from trustworthy manufacturers understood for their trustworthy and long lasting items.

Another factor to consider is compatibility. Guaranteeing that the construction parts are compatible with the specific make and version of the equipment is essential to stay clear of any kind of functional problems or damage. This includes verifying the measurements, requirements, and any type of extra demands for seamless integration.

In addition, taking into consideration the cost-effectiveness of the components is vital. While high quality should not be compromised, picking aftermarket components that provide a good equilibrium in between high quality and cost can aid in making the most of the worth of the financial investment.

Finally, availability and consumer assistance ought to additionally be taken into consideration. Go with building and construction parts that are readily offered and backed by excellent client support to deal with any kind of problems or queries promptly. By meticulously examining these factors, you can make enlightened decisions when picking aftermarket building components for your heavy equipment.

Installation Tips for Aftermarket Parts

To ensure a seamless and efficient installation procedure for aftermarket building and construction components on hefty equipment, careful interest to detail and adherence to producer guidelines are paramount. Before starting the installment, it is critical to extensively check the aftermarket parts to verify that they match the specifications of the initial components and are without any type of problems. Additionally, arranging the workspace and guaranteeing that the necessary devices are easily available can help simplify the installment process.

Following the supplier's installment directions is vital to assure appropriate fit and functionality of the aftermarket components. Any kind of discrepancy from these guidelines can cause substandard performance or perhaps potential safety and security dangers. It is also suggested to document the installation procedure, including any type of adjustments made or challenges encountered, for future recommendation.

Last but not least, carrying out a last assessment after the installment is full can aid determine any problems or mistakes that might have been forgotten - aftermarket construction parts. Evaluating the machinery to ensure that the aftermarket parts are operating appropriately is an important final action in the installment process

Upkeep Standards for Upgraded Equipment

For ideal efficiency and durability of updated machinery, adherence to specific upkeep guidelines is important. Regularly scheduled maintenance checks are important to ensure that all aftermarket parts are operating properly. This includes inspecting elements for deterioration, lubing moving components, and changing filters as required. Complying with the manufacturer's advised maintenance routine is highly recommended to prevent unexpected malfunctions and pricey repair services.

Along with regular maintenance, drivers must likewise take notice of any unusual noises, vibrations, or performance concerns that might develop. Attending to these problems quickly can protect against further damage to the machinery and its aftermarket components. Keeping detailed documents of upkeep tasks, fixings, and part replacements can help track the total wellness of the upgraded machinery and recognize any kind of recurring issues.

Additionally, correct storage space and cleaning treatments must be followed to protect the equipment from ecological variables that can speed up use a knockout post on aftermarket parts (aftermarket construction parts). By following these upkeep standards carefully, operators can optimize the advantages of their upgraded machinery and guarantee its ongoing reliability at work site

Cost-Effective Upgrades for Hefty Machinery

Applying strategic upgrades can significantly enhance the efficiency and efficiency of heavy machinery while keeping cost-effectiveness. When considering affordable upgrades for heavy equipment, it is crucial to prioritize enhancements that provide the most considerable effect on productivity without breaking the budget. One cost-efficient upgrade is the installment of innovative telematics systems. These systems supply real-time data on devices use, fuel consumption, and maintenance needs, permitting aggressive decision-making and lowering downtime.

Another cost-effective upgrade is the integration of GPS technology, which can maximize course planning, rise gas performance, and boost general work site performance. Upgrading to more sturdy tires or tracks can additionally be a wise financial investment, as they can enhance traction, minimize wear and tear, and inevitably extend the lifespan of the equipment. Furthermore, retrofitting older machinery with energy-efficient elements, such as LED lights or boosted hydraulic systems, can bring about long-lasting price financial savings through reduced power consumption and upkeep expenditures. By meticulously selecting and applying these affordable upgrades, hefty equipment drivers can optimize performance and effectiveness while remaining within budget constraints.

Verdict

In conclusion, aftermarket building and construction parts use countless benefits for enhancing heavy equipment. Generally, economical upgrades with aftermarket components can lead to enhanced performance and productivity in building and construction procedures.

Enhancing heavy machinery with quality aftermarket construction parts can dramatically influence the performance and longevity of your devices.Enhancing hefty machinery with aftermarket building and construction parts can considerably enhance efficiency and longevity.Furthermore, aftermarket building and construction components can provide cost savings contrasted to buying original equipment supplier (OEM) parts.To why not check here make sure a reliable and seamless setup procedure for aftermarket building and construction components on heavy machinery, thorough interest to detail and adherence to explanation supplier standards are paramount. Prior to beginning the setup, it is essential to extensively examine the aftermarket parts to confirm that they match the specs of the original parts and are totally free from any type of flaws.